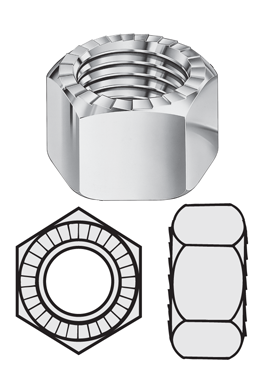

SPN-LOC Twin Spin Locknut

Posted on September 28th, 2016 by vaproTwin Spin Serrated Locknut

We offer two options with this nut – choose to have serrated locking elements on either the bearing surface only, or on both nut faces. Available in American Standard and Metric; Machine screw, hex finished, and jam nuts.

Serrations available on one or both sides

Available In

American standard and Metric: Machine Hex Finished Nuts, Heavy Nuts and 2H Nuts.

Materials

Steel Grade 2-5-8, Monel, Brass, Bronze, Aluminum Alloys and Stainless Steel

Thread

UNC, UNF or 8UN Series, Class 2B, 3B, Left Hand Thread and Metric

Finish

Plain, Zinc, Cadmium, and other platings and coatings